The company was born in 1990, in Alba Iulia, as a small family business. It has grown gradually, combining experience with the highest quality standards.

The brand was born from the desire to offer customers products with a modern design, using the best quality raw materials.

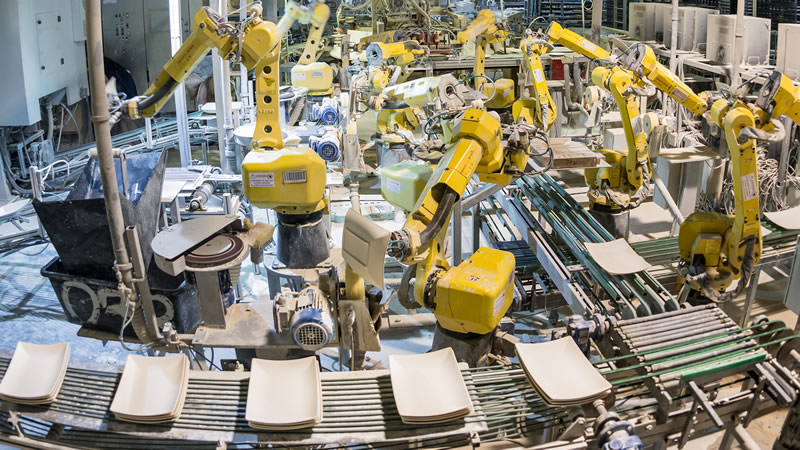

At the beginning, the company’s activity consisted of the production of ornamental and decorative items produced in small quantities, which were then sold on the domestic market. The year 1996 brought the first major change in the approach to the sales strategy, the company starting a business relationship with the Swedish concern IKEA, for which it began to produce more and more, year by year. Thus, from a small family business, the company began to transform into a production facility oriented towards series production, with modern machinery and sales on the foreign market.

Currently, the company has over 50 preparation mills, 2 atomizers for the production of atomized powder, 20 isostatic presses, 10 firing furnaces, 30 glazing machines and over 200 industrial robots.

Project details

Client: IPEC

Implementation date: 2021

Field of activity: Production

Company website: IPEC

Crosspoint implementation

Project features

The implementation of a WMS solution within IPEC came as a necessity following the increase in the complexity of logistics processes by splitting stocks between the own finished product warehouse and the delivery of some customer groups through an external logistics center whose IT solution had to be integrated. The main functionalities implemented include:

- Customer order management

- Transport planning

- Production delivery

- Traceability of specific stock parameters:

- Production date

- SSCC pallet

- Type FSC

- Integration of stock movements with the ERP solution used

- EDI integration

- Reception of planned trucks and Quality Inspections

- Document Management

- Billing

Similar projects